We recently delivered a pair of single IBC Lubestations and a waste oil Lubestation waste oil skid to Talison Lithium….

Talison Lithium is a prominent global lithium mining and production company that was formed in 2009. Talison Lithium specialises in the exploration, development, and production of lithium minerals, which are essential components for manufacturing lithium-ion batteries used in electric vehicles, portable electronic devices, and renewable energy storage systems.

While interest in lithium and other elements needed for renewables seems relatively new, the company’s Greenbushes mine has actually been in operation for over 30 years and has played a crucial role in meeting the growing global demand for lithium.

The company approached RETRA Fluid Handling Systems to help upgrade their lube room.

“Talison Lithium, a world-leading lithium mineral producer, is always looking for ways to improve,” said RETRA key account manager Saxon McEwen.

“They identified their fixed plant lube room as an area of improvement. They were experiencing contamination issues, with water and dust getting into their fluids. The company also mentioned that they were looking to relocate the lube room, making our containerised Lubestation a good fit.”

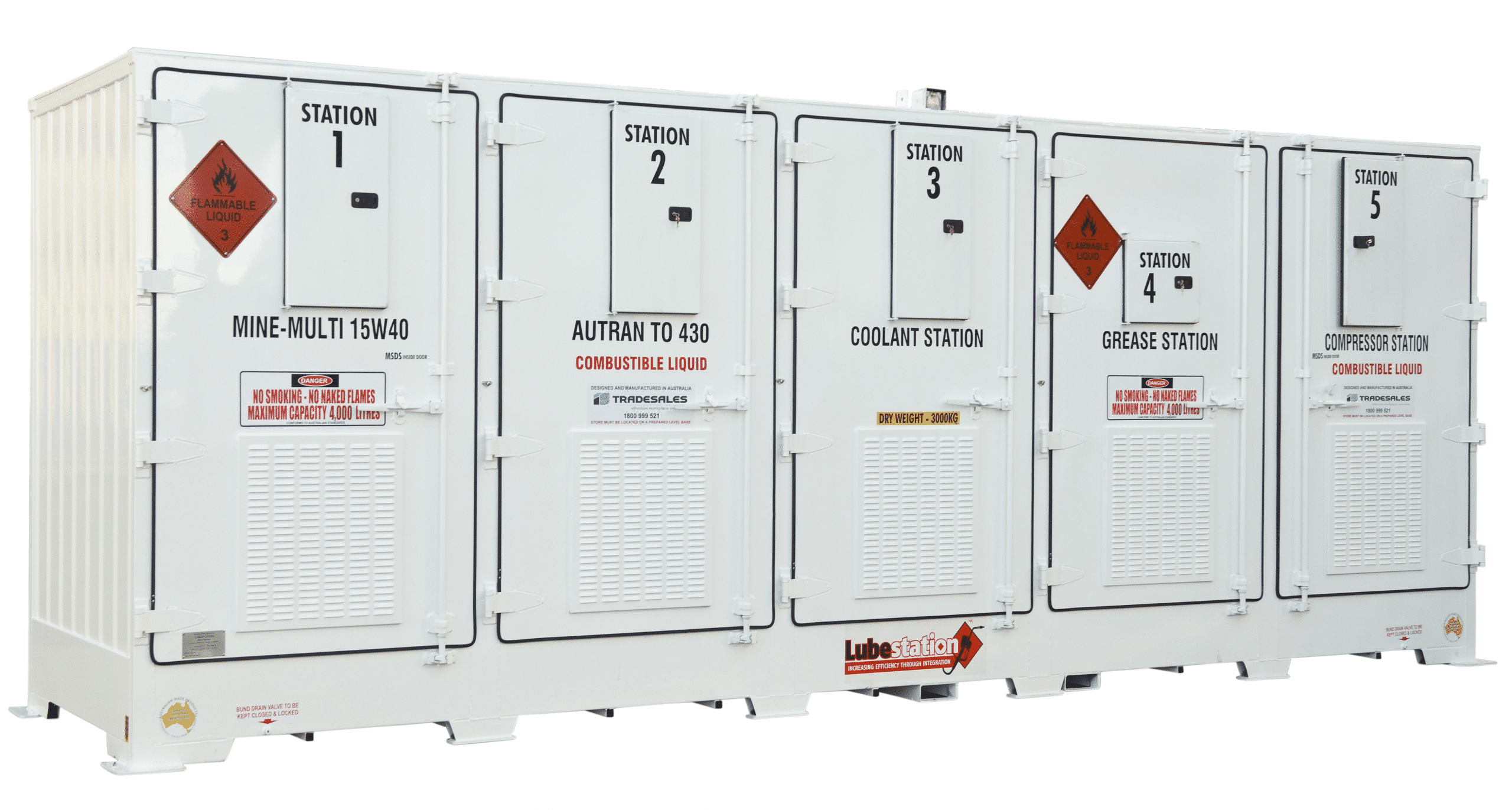

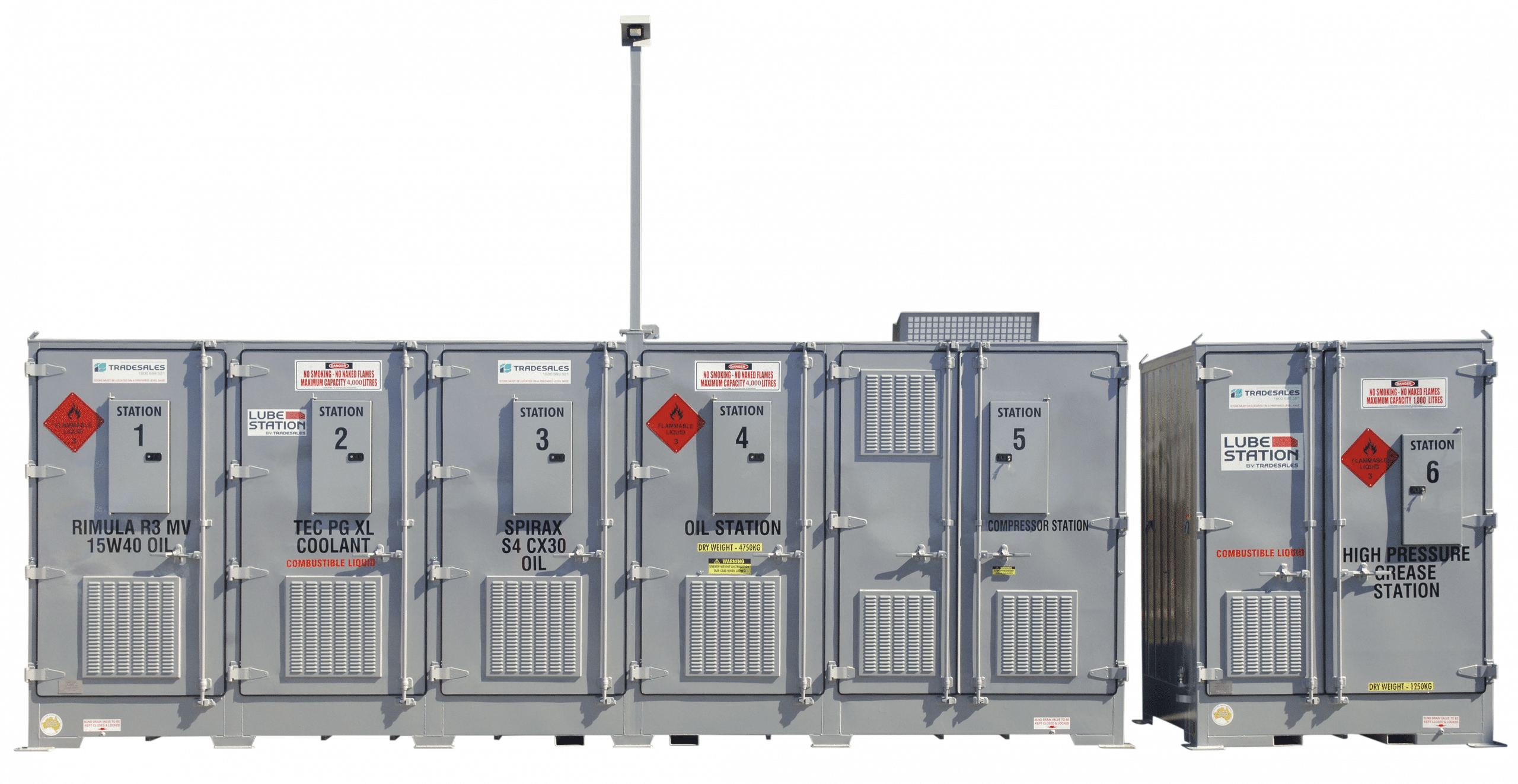

A 20-foot fixed plant Lubestation was designed for Talison, including six different oils being pumped from 1000 litre IBCs through Graco pumps. The company chose to swap from 205-litre drums to IBCs to prevent manual handling issues.

“The fluids from the IBCs run through stainless-steel pipes to a series of taps which can then be dispensed into the smaller 20-litre oil-safe containers that the guys are using on-site,” said Saxon.

“Another feature of this Lubestation is the intrinsically safe lighting, which means there’s no risk of sparks. That gives you piece of mind when storing combustible liquids.”

The Lubestation is fitted with bunded shelving, which will be used to store smaller 20-litre drums when not in use by maintainers. The Lubestation is also bunded to AS 1940 standards to capture leaks and spills.

“Talison has been great to work with. They initially contacted us through the RETRA website, and within a week, we had visited the site and gathered the input from the maintenance crew,” said Saxon.

“We returned within two weeks after the visit with GA drawings and a quote. Once the quote was approved and drawings signed off, fabrication started, and the unit was completed in about six weeks.”

Each Lubestation is easily portable and can be moved to different areas of a site, saving on capital costs while protecting lubes, pumps, reels and hoses from the harsh elements encountered in. These relocatable site solutions also prevent cross-contamination of oils, grease and coolant, giving you the peace of mind that you’re putting fresh fluids into your expensive mobile or fixed plant equipment.

For more information on Lubestation, call 1300 242 504, email sales@retragroup.com.au or visit www.retragoup.com.au.