We recently delivered a pair of single IBC Lubestations and a waste oil Lubestation waste oil skid to Talison Lithium….

Problem

Australia’s biggest nickel mining operation was preparing to conduct a magnetic survey in a remote WA location. This survey would map new mineral bodies and provide essential data for future mining operations.

This project required cable reels that could store, transport, and handle 3 km of magnetic cable. Without this solution they couldn’t survey the land with the volume and efficiency necessary for their fast-moving operations.

Solution

Our client’s previous surveying contractor had developed their own makeshift reels. For this project, they needed a manufactured reel with higher performance, durability, and reliability.

We worked closely with the end-users to ensure they got the best reel for the job. Our team went through three design revisions before sending out a prototype reel for the surveyors to try. The design was finalised using their feedback and production started.

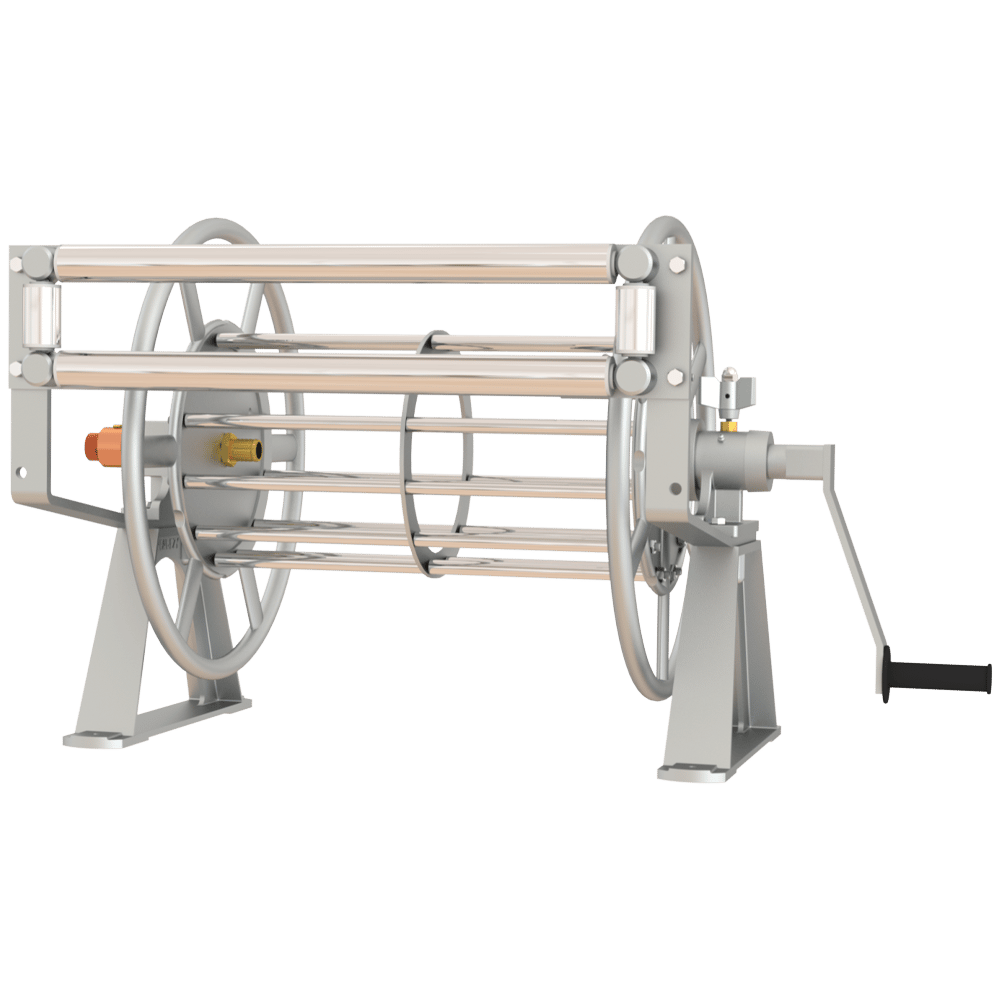

The final solution was a stackable manual rewind cable reel, built tough enough to handle any challenge.

We worked closely with the end-users to ensure they got the best reel for the job. Our team went through three revisions of the design before sending out a prototype reel for the surveyors to try. The design was finalised using their feedback and production started.

This cable reel uses our lightweight cast-aluminium wheels and drum frame, incorporated into an SHS steel frame. This frame allows the reels to stack vertically, adding extra rigidity and making for easier storage and handling. The handle is secured to the axle using a hand-wind bolt — secure enough not to come off during use but easy to remove for storage and transport.

Result

Each reel can hold 500 m of the 16 mm magnetic cable. Cable is wound onto the reels which are stacked three high and transported by LV to the exploration site. There they are unloaded by hand and carried to the precise survey locations for use.

The reels allow for easy and efficient transport and handling of cable. Storing cable on an individual, stackable reel removes the safety hazards that would occur with large amounts of cable on one roll.

Our client was happy with the outcome and has recommended their surveying contractors use these reels for future projects. We recommend this reel to anyone needing a solution to safely and efficiently handle large amounts of cable.